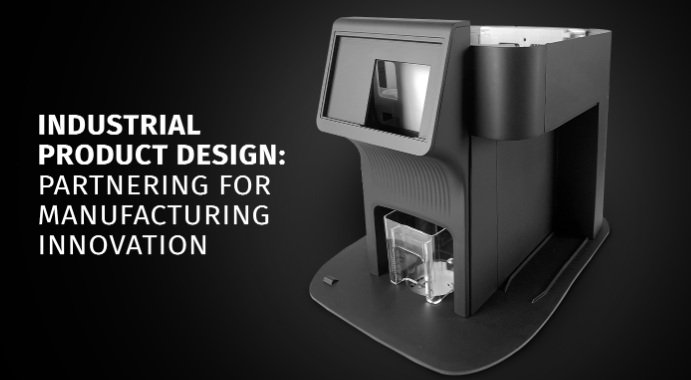

What happens when your next breakthrough product is not a creation in a factory but rather in a design studio that understands both manufacturing and creativity?This is the question at the centre of industrial innovation.

Production capacity is no longer a determining factor in manufacturing success. It is influenced by how smartly products are designed, engineered, tested, and refined, far before they actually get to the shop floor.

Industrial product design is no longer a secondary aesthetic consideration but an element of strategic collaboration that directly determines cost-effectiveness, scalability, sustainability, and competitiveness in the market. For manufacturers and startups alike, partnering with the appropriate industrial product design companies it’s no longer an option; it is a necessity.

Let’s see how partnering with industrial product companies drives innovation in manufacturing.

Industrial Product Design: The Foundation of Manufacturing Innovation

Innovation in manufacturing is not initiated on the factory floor at the design stage. All design choices have a direct impact on tooling complexity, material efficiency, assembly time, quality, and overall production cost.

Design for Manufacturability (DFM) is incorporated into the modern design of industrial products, especially at the outset. Rather than creating a product first and correcting it later, products are developed keeping actual manufacturing limitations in mind. This method radically decreases time-to-market, reduces waste, and prevents expensive delays in production ramp-up.

A skilled Industrial Product Designing Company in India, like Cubein, gives an added advantage in this case. Having been exposed intensively to global quality production requirements as well as the varying manufacturing ecologies, Indian design teams know how to strike a balance between innovation and viability. The outcome, products that are not only innovative but also practical, scalable, and manufacturing-ready.

Why Strategic Design Partnerships Matter More Than Ever

The industrial product design has evolved from an outsourced implementation to a strategic long term partnership.Even the most successful manufacturers do not consider design firms as external vendors , but incorporate them into their innovation ecosystem.

Market data also indicates this change. The global product design market is predicted to be about USD 32.93 billion by 2030 as more companies depend on cross-functional design and manufacturing partnerships to accelerate innovation and minimize development risks. The data also give a clear indication that companies are increasingly investing in integrated design ecosystems in which designers, engineers, and manufacturers are functioning as a single unit.

Design and Manufacturing Working as One:

With industrial designers working hand-in-hand with engineering, sourcing, and manufacturing teams, products reach production faster. Design cycles become smarter due to the real-time information about the materials, tooling, and assembly process.

This teamwork model allows:

- Rapid verification and prototyping

- Reduced production risks

- More effective alignment between market demands and engineering realities

How Industrial Product Design Drives Manufacturing Innovation

Optimisation of costs without affecting quality: 70% of manufacturing cost depends on product design decisions. The choice of the strategic materials, simplified assemblies, and optimum number of parts saves a lot of money without compromising performance.

Faster Time-to-Market: Integrated design processes eliminate delays associated with design and production misalignment. Manufacturers can introduce products at a faster rate, react to customer feedback within a short period, and keep pace with competitors.

Scalable, Future-Ready Products: Products that are well designed are not only manufacturable; they are scalable. Industrial design foresees future alterations, improvements, and the expansion of the market without the thorough redesigns.

Sustainability Built into Manufacturing: The initiation of sustainable manufacturing starts with the design process. Recyclable material, reduced energy consumption, production processes, and design of industrial products are all important aspects of achieving ESG objectives.

Industrial Product Design for Startups vs. Established Manufacturers

For Startups

Industrial product design gives start-ups an advantage of:

- Eliminating product-market risk

- Developing investor-ready prototypes

- Creating the most valuable players to appeal to early customers

In the Case of Established Manufacturers

Established companies use design partnerships to:

- Modernise legacy products

- Enter new markets faster

- Make better use of margins through smart designs

In either scenario, the right product design partner transforms concepts into reality, which can be manufactured easily.

The Rising Role of India in Global Industrial Product Design

India has quickly emerged as the industrial product innovation hub all over the globe. In addition to being cost-effective, the country now has:

- Global design engineering excellence

- Powerful exposure to international manufacturing standards

- Experience in automotive, healthcare, electronics, consumer goods, and industrial equipment

The unique advantage that an industrial product design company in India can offer is the design for both emerging and global markets. Products are designed in such a way that they can be scaled effectively while being customizable to various regulatory and user needs.

This article is beneficial to startups and manufacturers who want to pursue this direction. For the article, click here.

Conclusion

The innovation in manufacturing is no longer a process based on machinery alonebut is influenced by smart design decisions that are made at the early stage of the product lifecycle. By engaging the appropriate industrial product design company, the challenges of manufacturing are converted into growth, efficiency, and differentiation opportunities.

The combination of design, engineering, and manufacturing all into a single approach opens up accelerated innovation and long-term prosperity for any company. This is the philosophy behind the way Cubein works with progressive manufacturers, transforming the complex concepts into production-ready, market-winning products.

| Looking for an Industrial Product Design Partner Who Understands Manufacturing? Cubein is your ultimate destination. Contact now! |

FAQs

1. What is the significance of Industrial Product Design Companies to manufacturers?

They make products functional, manufacturable, cost-effective, and user-centric; these minimise production risks and reduce time-to-market.

2. What is the value addition of an Indian Industrial Product Design Company to the world?

Indian design companies have integrated world standards, engineering skills, and cost efficiency, making them the best collaborating partners in international manufacturing projects.

3. Why is a company considered to be the best product design company in India?

The best design partners, like Cubein, are characterised by end-to-end capabilities, manufacturing-first thinking, cross-industry experience, and high levels of collaboration.

4. Is industrial product design able to enhance sustainability in manufacturing?

Yes, the design choices affect the material utilisation, energy consumption, and the impact on the product life cycle, making sustainability possible at the very beginning.

Refresh Date: January 30, 2026